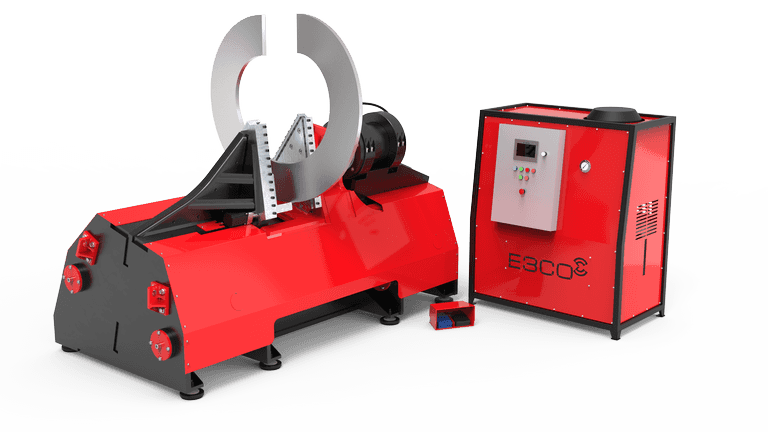

for screw spiral manufacturing

Our machines bend coils of screws up to 50 mm thick of any geometry, any steel grade. The equipment is equipped with modern CNC controls and software, which allows for observing accurate repeatability and perfect geometry of the coils.

DELIVERED WORLDWIDE

CNC MACHINES

Fill out the form

Our manager will contact you

By clicking Send you agree to the processing of personal data

We know these problems, as we have been facing them ourselves for 5 years

Augers are actively used in many fields of activity. Intensive usage requires their periodic replacement. You can regularly buy them, increasing the burden on the budget, or produce them yourself, facing several problems:

It is not possible to achieve

the correct screw geometry

and exact dimensions

the correct screw geometry

and exact dimensions

The process of making

one segment

takes too long

one segment

takes too long

You have to constantly change

the forming tool, which

increases the time of work

the forming tool, which

increases the time of work

It is difficult or impossible

to change the height of the flange

to change the height of the flange

Difficulties arise during the bending of great-thickness metal. The purchase of modern equipment will solve this problem, paying off in just 2.5 months for the manufacture of 3 augers per month.

We will help with this — we will supply your company presses of proper quality

The result will exceed all your expectations

Increase employee loyalty by reducing workloads

Ability to pay more attention to other production tasks

Ability to pay more attention to other production tasks

Ability to produce auger spirals for sale to other enterprises

Increased attention to your products

by customer partners

Increased attention to your products

by customer partners

Increasing the profitability of your manufacturing

Reduced current production costs and risks of breakdowns of used augers

Reduced current production costs and risks of breakdowns of used augers

Reducing the time required to produce an auger

Ability to produce perfect augers of any size and configuration

Ability to produce perfect augers of any size and configuration

Reduced injuries due to the strength and smart design of the machine and the quality of the augers

save with us

per year

$1.5 million

79%

reduction

of downtime

of downtime

Innovation clearly

The obvious advantages of our machines

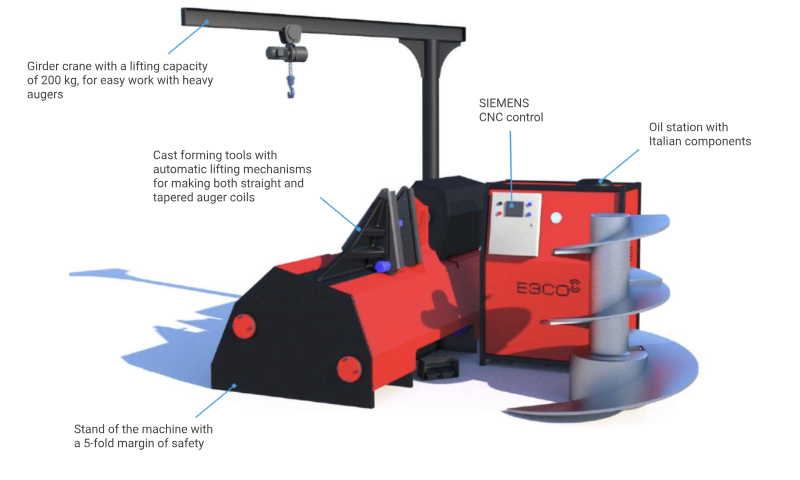

Controls for left- and right-handed operators

The machines are versatile and can be operated by both right- and left-handed operators.

The machines are versatile and can be operated by both right- and left-handed operators.

CNC complex

The equipment is computer numerically controlled, which rules out any errors.

The equipment is computer numerically controlled, which rules out any errors.

Automatic calculation of parameters

The program instantly calculates the required screw segment parameters based on the data entered by the operator.

The program instantly calculates the required screw segment parameters based on the data entered by the operator.

Precise Settings

The geometry of the coil is perfectly accurate, with no deviations in size or configuration.

The geometry of the coil is perfectly accurate, with no deviations in size or configuration.

Stand of the machine with a 5-fold margin of safety

The machine is capable of withstanding serious loads in intensive operation without the slightest damage.

The machine is capable of withstanding serious loads in intensive operation without the slightest damage.

Ease of use

The equipment works at maximum efficiency with minimal effort on the part of the operating personnel.

The equipment works at maximum efficiency with minimal effort on the part of the operating personnel.

Coils of any diameter

The outer diameter of the auger coil

can be any size —

there are no restrictions.

The outer diameter of the auger coil

can be any size —

there are no restrictions.

One forming tool

Any number of different auger segments

can be produced without

changing the forming tool.

Any number of different auger segments

can be produced without

changing the forming tool.

Work with any steel grades. Any grade of steel is suitable for the manufacture of augers.

All-inclusive

Step-by-step cooperation plan

Production

We find out your wishes, plans, and needs f your manufacturing. We conclude an official contract. We will design and install the machine to your requirements.

Delivering

We will ship ready-made equipment within the specified time. We ensure its timely and careful delivery to your facility.

Assembly and commissioning

Installation and commissioning are performed by qualified masters from our team.

Teach

Teach your specialists to work on new equipment, including CNC and software use.

We will keep our finger on the pulse

We will answer any of your questions during the operation of the equipment of our manufacture. If necessary, we will assume the technical maintenance and repair of the machine.

Provide parts and spares.

Provide parts and spares.

Screw products

We do not have any restrictions for the production of augers of any geometry. Our products are high — quality and at the same time cheaper than any analogues due to low labor costs and production on the spot, in Russia.

We produce screws with a thickness of 2 to 50 mm in the shortest possible time on our own professional equipment. The outer and inner diameter is not limited. Perfect repeatability and geometry are guaranteed.

With the help of our own equipment in the shortest possible time.

We will develop design documentation, implement a project of any complexity on a turnkey basis.

Eurasian Plant of Construction Equipment

global quality standards

We strictly adhere to high-quality standards, focusing on rigid international requirements.

We supply screw spiral machines without intermediaries - to minimize the costs for future users.

We supply screw spiral machines without intermediaries - to minimize the costs for future users.

It's time to take responsibility for our words

No, equipment tooling can be formed individually — according to the customer's technical specifications.

No. The cost of tooling is taken into account when we calculate the final price of the equipment.

We do our own maintenance and repair of the equipment we produce. If necessary, we will train your technical personnel.

Our products are delivered worldwide, without territorial restrictions.

We promptly process and fulfill any requests. The exact timing is calculated individually and specified in the contract. The maximum time for the execution of the application is 3 months.

Yes. 60% of the total cost of the order is paid before we start assembling the machine. Аnd the remaining 40% is paid before the shipment of the finished equipment.

geography of supply

We offer a profitable solution for enterprises that use auger spirals or produce augers for sale. Our equipment allows you to save costs and labor costs significantly, increasing the profitability of production.

While you read this,

2 of your competitors

are already

2 of your competitors

are already

calling

us

us

Contact us now to learn more about your options and the prospects for purchasing our machines. We'll be happy to answer any of your questions, give you personal recommendations, choose the best option for equipment, and offer the best price.

© 2022. All rights reserved.